Indus Motor Company Faces Operational Challenges Amid Supply Chain Woes

Indus Motor Company (IMC), a prominent automobile assembler known for its Toyota vehicles in Pakistan, is currently facing a series of operational challenges that have compelled the company to implement its 6th round of Non-Production Days (NPDs) in the current year. This decision was prompted by a persistent shortage of crucial parts and inventory, which can be primarily attributed to stringent import restrictions.

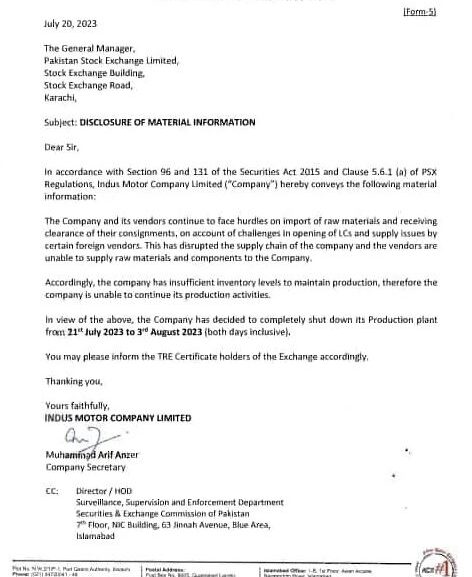

In an official announcement made to the Pakistan Stock Exchange (PSX), IMC communicated that its Toyota assembly plant would undergo a temporary shutdown from 21st July to 3rd August 2023. This elongated period of 14 NPDs adds to an already substantial list of non-production days that the company has experienced throughout the year.

Notably, IMC previously had to resort to complete plant closures during specific periods in response to inventory deficiencies. These instances occurred from June 26 to June 27, June 3 to June 8, May 2 to May 3, March 24 to March 27, and from February 1 to February 14.

The challenges faced by IMC and other local assemblers in Pakistan’s automotive industry can be traced back to persistent issues within the supply chain. Hindrances encountered during the importation of essential raw materials have emerged as a significant concern. Among these challenges, the non-issuance of Letters of Credit (LCs) takes center stage. The absence of LCs leads to delays and hampers the smooth flow of goods, exacerbating the already existing inventory shortage predicament.

This situation has far-reaching implications, not only affecting IMC’s manufacturing operations but also reverberating through its network of suppliers and the broader automotive ecosystem in Pakistan. The inability to access vital components and raw materials not only disrupts production capabilities but also creates market instability. Moreover, this predicament can potentially result in financial setbacks for various stakeholders within the automotive industry.

As IMC grapples with these intricate challenges, the company, along with other players in the sector, is actively monitoring ongoing developments and diligently seeking viable solutions to alleviate the strain on the supply chain. Such endeavors may entail engaging with relevant authorities to address the issuance of LCs or exploring alternative sourcing strategies for essential materials.

This situation serves as a poignant reminder of the interconnectedness of global supply chains and emphasizes the crucial role of a stable and efficient import-export environment for fostering sustainable growth in various industries. The successful resolution of these issues holds immense importance, not only for IMC’s continued success but also for bolstering Pakistan’s manufacturing sector as a whole. By overcoming these obstacles, the nation can ensure a seamless flow of goods and services, fostering economic growth and prosperity.